Case Study: Improving Performance Inside Cloud Kitchens

Final Design

All mockups have been constructed for the article and don’t use real Delivery Hero internal data.

Know that feeling when you want to order Pizza but there's no Italian restaurant nearby?

Cloud Kitchens are equipped spaces designed exclusively for delivery that address those choice gaps, providing an opportunity for restaurant owners to expand their food brands to new markets with minimal investment.

New owners entering the kitchen industry for the first time though, ignore how to leverage Cloud Kitchens to unleash their full business potential.

Cloud Kitchen from the Outside (Dubai).

Problem

Without the right tools, things can get pretty messy during high-activity periods (peak times.)

Printed receipts getting lost, miscommunication between staff, and order delays are especially common in food brands dealing with 50+ orders a day.

These challenges are bad news to both the food brand’s owner and the kitchen business, as they contribute to higher fail rates (order cancellations), bad reviews, and longer food preparation times.

My Role

As a Senior Product Designer, my responsibilities included:

Partner with the Product Manager to drive discovery

Lead Ideation and Design

Partner with Engineering for successful implementation

Goal

The overall goal of the project was to help increase the performance of inexperienced partners and streamline their operations with technology.

Success Metrics

Reduce Fail Rate

Reduce Prep Time

Increase Happiness (CSAT and NPS)

Discovery and Opportunities

To understand where new partners struggled, we ran a field study and conducted 10+ interviews inside our Cloud Kitchens in Dubai (United Arab Emirates) and Riyadh (Saudi Arabia).

Too Many Devices

A device per platform

Orders were coming in from various platforms, each of them requiring its own device. Additionally, the Cooking Staff had to transfer each order to a central system (POS) to keep track of all orders.

Hence, processing orders was chaotic due to a lack of device integration.

Printed Receipt Chaos

Printed receipts piled up during peak times

During peak times, printed receipts tended to accumulate, causing confusion, errors, and taking up valuable workspace.

Furthermore, these receipts were prone to get lost or become dirty, contributing to increased failure rates, negative reviews, and longer preparation times.

Waste of Movement

Button at the entrance to call the robot

Dispatcher robot

When an order’s ready, it has to get from where it’s cooked to the drivers waiting to deliver it. The facilities are big, so walking from a stall to the drivers takes about a minute. The cooks can’t do it all themselves because they need to stay fresh for the next order.

So what’s the fix? A robot or a human dispatcher.

The cooks press a button placed at the entrance when the order’s nearly done, and after a minute, the dispatcher comes over, grabs the food, and takes it to the drivers.

But there was an even better way: Shortening the distances.

When the cooks are all working in the kitchen, things get cramped, and moving around becomes tough. Reaching the button over and over again for every order wastes a lot of time, plus it leads to delays, cold food, and drivers waiting around.

In a nutshell, notifying that an order was ready to pick up, required excessive motion. The process had to be redesigned to enhance the work of personnel and increase health and safety levels.

No Performance and Order Urgency Indicators

Ultimately, it was the cooking staff who were responsible for improving performance.

But at the time, there were no real-time indicators on

Performance (#Orders and Preparation Time)

Oder urgency (rider’s location and count-down)

The Story of an Order

The workflow inside the kitchens looked more or less like this:

Story of an Order (Funny images from AI prompts.)

Design Decisions

POS Integration

How might we make it possible for the Cooking Staff to accept and see all orders coming from different platforms?

Integrate all platforms in 1 application to simplify order processing.

Kitchen Display System

How might we prevent printed order slips from piling up and getting lost during peak times?

Bring all orders together in a web app with horizontal scrolling to simulate the direction of an order ticket rail

Optimize for small viewport sizes (tablet devices) to keep device placement as flexible as possible

Make it available as a PWA (Progressive Web App) to

- Deliver a native-like UX

- Increase screen real estate

- Increase performance in poor internet connection locations

- Ensure usage in any platform including desktop and mobile devices

- Decrease development effortUsage of Dark Mode to adapt to the light conditions inside the stalls, increase contrast

Increase font size to be seen from distances around 5 meters away

Horizontal scrolling

Actions on Orders and Views

How might we make it easier for the cooking staff to communicate order statuses inside and outside the stall?

Actions on orders in the KDS to change status between “Cooking”, “Packing” and “Ready”

Filter orders by status and organize them in tab-views

Actions on orders and tab views

Tab views

Mark an order as “Ready” to notify the Dispatching Area

Order Prioritization

How might we make it easier for the cooking staff to prioritize orders?

Assign orders an urgency color code based on

- Rider Location == Estimated Time of Arrival — Current Time

- Remaining Prep TimeShow an icon when the driver is nearby (within a geofence of 150m)

Add a Countdown timer in the orders to track time efficiently

Highlight customer notes

Order Urgency Matrix (color code)

Order color codes, countdown timer, and highlighted customer notes

Performance Indicators

How might we enforce self-improvement?

Display daily Average Prep Time = Cooking Time (🧑🍳) + Packing Time (🛍️) (tracked by the actions on orders)

Show total of daily orders

Leverage empty states with good microcopy to educate users

Total Daily Orders and Avg Prep Time

Empty state – “All” view

Empty state — “Cooking” view

Empty state to educate Cooking Staff on vendor delay metrics.

Empty state to educate Cooking Staff on vendor delay metrics.

Impact

Results and Outcomes

-10% Fail Rate

-10% Preparation time

90% CSAT

+70 NPS

Cost cuts by saving on Receipt Paper

Better cooking staff organization

Accurate collection of key data points like Prep Time per stall

Decrease in missing customer notes which resulted in better reviews

For confidentiality reasons, I have omitted the actual values for these metrics.

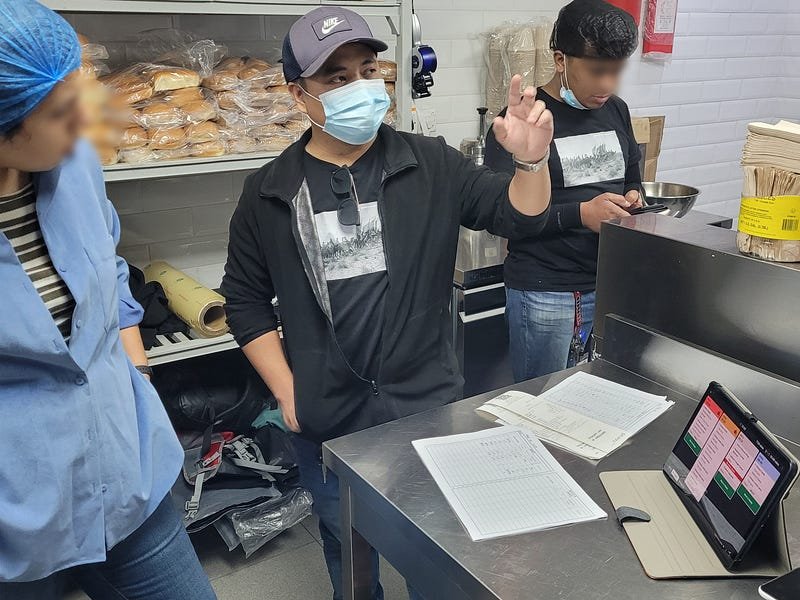

Superpowering Cooks

Cooks efficiently working after adopting our Kitchen Display System.

Taking a Stairway to Food Heaven

The product expanded beyond our horizons and made its appearance in music festivals like Lollapalooza Stockholm.

Reflection

At the time I joined, there was already an embryonic MVP for this project.

But it wasn’t tailored for optimal tablet usage and was missing fundamental features to help cooking staff get their jobs done.

This case study is another instance showcasing the substantial Return on Investment (ROI) of UX Design and Research.

Testing with Cooks and getting the buy-in from their Managers.